Rubber Flat Festoon Cables 300/500 V

Rubber Flat Festoon Cables 300/500 V

Applications

Used for festoon and handling systems, machine tools, lifts and e-chain cable carrier systems. For applications with high mechanical stress and frequent bending in one plane only.

Design

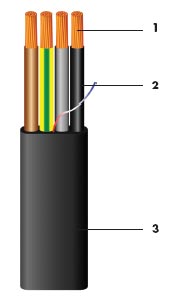

| 1. Conductor | Flexible, plain copper,≤ 25 mm2: extra flexible stranded, class 6 ≥ 35 mm2: flexible stranded, class 5 according to IEC 60228/ DIN VDE0295 |

| 2. Insulation | EPR rubber compound 3GI3 refer to DIN VDE 0207 part 20 |

| 3. Outer sheath | Rubber compound 5GM3 refer to DIN VDE 0207 part 21 |

| Colour: | black |

Marking

RHEYFLAT-N NGFLGOEU-J

Number of cores – Cross-section

300/500 V – NEXANS – year

Cores Identification

DIN VDE 0293 part 308/HD 308 S2

4 cores: green/yellow – brown – black – grey

5 cores: green/yellow – blue – brown – black – grey

≥ 5 cores: black with white printed numbers – green/yellow

Standards

DIN VDE 0250 part 809

Mechanical properties

| Tensile stress of the conductor | static | 15 N/mm2 |

| dynamic | 30 N/mm2 | |

| Bending radii | according to DIN VDE 298 | |

| Tests | Bending test | |

| Festoon speed | up to 180 m/min |

Chemical properties

Oil resistant.

For indoor and outdoor applications. Moisture, UV and ozone resistance.

Flame-retardant according to IEC 60 332 part 1.

Electrical and Thermal properties

| Nominal voltage | Uo/U | 300/500 V |

| Maximum operating voltage in AC systems | Um | 500 V |

| Maximum operating voltage in DC systems | Vm | 750 V |

| Test voltage (according to DIN VDE 0250 part 809) | 2.0 kV in AC | |

| Current rating (A) | according to DIN VDE 0298 part 4, | |

| Max. temperature at the conductor: | ||

| – in service | + 90 °C | |

| – under short-circuit conditions | + 250 °C | |

| Max. surface temperature: | ||

| – Fixed installation | – 50 °C up to + 80 °C | |

| – Mobile Operation | – 35 °C up to + 80 °C | |

RHEYFLAT®-N NGFLGOEU-J

| Number of cores and nominalcross-section (mm2) |

Outer dimensions approx. (mm) |

Weight approx. (kg/km) |

|

| CONTROL | 4 x 1.5 | 6.2 x 17.5 | 200 |

| 5 x 1.5 | 6.2 x 21.5 | 240 | |

| 7 x 1.5 | 6.2 x 29.0 | 360 | |

| 8 x 1.5 | 6.2 x 31.5 | 370 | |

| 10 x 1.5 | 6.5 x 40.0 | 520 | |

| 12 x 1.5 | 6.5 x 47.0 | 620 | |

| 24 x 1.5 | 12.5 x 55.0 | 1,300 | |

| 4 x 2.5 | 7.5 x 21.0 | 280 | |

| 5 x 2.5 | 7.5 x 27.0 | 400 | |

| 7 x 2.5 | 7.5 x 35.0 | 520 | |

| 8 x 2.5 | 7.5 x 39.0 | 550 | |

| 12 x 2.5 | 8.0 x 56.0 | 800 | |

| 24 x 2.5 | 16.0 x 68.0 | 1,850 | |

| POWER | 4 x 4 | 9.0 x 26.0 | 410 |

| 5 x 4 | 9.0 x 32.0 | 560 | |

| 7 x 4 | 9.0 x 42.0 | 700 | |

| 4 x 6 | 9.5 x 29.0 | 600 | |

| 5 x 6 | 9.5 x 35.0 | 650 | |

| 7 x 6 | 9.5 x 42.0 | 850 | |

| 4 x 10 | 11.0 x 33.0 | 800 | |

| 5 x 10 | 11.0 x 44.0 | 1,000 | |

| 4 x 16 | 13.0 x 38.0 | 1,150 | |

| 5 x 16 | 13.0 x 50.0 | 1,450 | |

| 4 x 25 | 15.0 x 49.5 | 1,700 | |

| 5 x 25 | 16.0 x 60.0 | 2,200 | |

| 7 x 25 | 16.0 x 80.0 | 3,060 | |

| 4 x 35 | 17.0 x 55.0 | 2,200 | |

| 7 x 35 | 17.0 x 88.0 | 3,900 | |

| 4 x 50 | 19.0 x 63.0 | 3,000 | |

| 4 x 70 | 22.0 x 71.0 | 4,000 | |

| 4 x 95 | 25.0 x 80.0 | 5,300 | |

| 4 x 120 | 27.0 x 86.0 | 6,400 |