Basket Spreader Cables

Basket Spreader Cables

Applications

Special control cablesfor load lifting devices such as spreader with high mechanical stress in vertical free-fall basket operation in dry, humid and wet rooms and for outdoor marine environments. Used e.g. in electro-hydraulic telescopic spreader for:

- Ship to Shore (STS) cranes,

- Rail Mounted Gantry cranes (RMG),

- Rubber Tired Gantry cranes (RTG),

- Intermodal stacking cranes,

- Mobile harbour cranes …

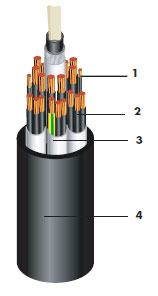

Design

| 1. Conductor | Extra flexible, plain copper, acc. to DIN EN / IEC 60228 class 6 |

| 2. Insulation | PVC compound according to DIN EN 50363-3 |

| 3. Core assembling | Bundle stranding with/without EMC screen and heavy weight elements |

| 4. Outer sheath | Thermoplastic polyurethane according to DIN EN 50363-10-2 |

| Colour: | Black |

Marking

eg RHEYCORD(BS) YSLZ3SOE-J 44 x 2.5

300/500V I NEXANS I year

Cores Identification

DIN VDE 0293 part 308 white cores with black printed numbers + green/yellow core.

Standards

International Nexans specification UL FILE-CCN: E60419-ZIPF

Mechanical Properties

| Tensile stress of the conductor | static | 15 N/mm2 |

| dynamic | 30 N/mm2 | |

| Bending radii | according to DIN VDE 298-3, | |

| see construction characteristics | ||

| Tests | alternating/reversed bending test, torsional resistance test | |

| Travelling speed | up to 160 m/min | |

Chemical properties

Oil resistant.

For indoor and outdoor applications. Moisture, UV and ozone resistance.

Electrical and Thermal properties

| Nominal voltage | Uo/U | 450/750 V |

| Maximum operating voltage in AC systems | Um | 550 V |

| Maximum operating voltage in DC systems | Vm | 825 V |

| Test voltage | 2.0 kV in AC | |

| Current rating (A) | according to DIN VDE 0298 part 4, | |

| Max. temperature at the conductor: | ||

| – in service | + 70°C | |

| – under short-circuit conditions | + 150°C | |

| Max. surface temperature: | ||

| – fixed installation | -20 °C up to + 60°C | |

| – mobile operation | – 20 °C up to + 60°C | |

| Number of cores andnominal cross-section | Outer diameter | Weightapprox. | ||

| (mm2) | Min.(mm) | Max.(mm) | (kg/km) | |

| CONTROL | 48 x 1 | 32 | 35 | 2100 |

| 30 x 2.5 | 32 | 35 | 2200 | |

| 36 x 2.5 | 35 | 38 | 2600 | |

| 42 x 2.5 | 38 | 41 | 3100 | |

| 44 x 2.5 | 37 | 40 | 3250 | |

| 20 x 3.5 | 30 | 33 | 1850 | |

| 24 x 3.5 | 32 | 35 | 2350 | |

| 30 x 3.5 | 35 | 38 | 2800 | |

| 36 x 3.5 | 39 | 42 | 3700 | |

| 42 x 3.5 | 43 | 46 | 4700 | |

| 54 x 2.5 | 46 | 49 | 4500 | |

| 24 x 12 AWG | 33 | 35 | 2200 | |

| 36 x 12 AWG | 39.5 | 42.5 | 3500 | |

| 42 x 12 AWG | 43 | 46 | 3900 | |

| 44 xf 12 AWG | 43 | 46 | 3800 | |

| Control with Optical Fibre Element | 32 xf 3.5 + OFE | 39 | 42 | 3550 |

| Control With Concentric Screen | 48 x 1 | 38 | 41 | 2400 |

| 30 x 2.5 | 38 | 41 | 2550 | |

| 36 x 2.5 | 35 | 38 | 2950 | |

| 42 x 2.5 | 43 | 46 | 3700 | |

| 20 x 3.5 | 36 | 39 | 2100 | |

| 24 x 3.5 | 38 | 41 | 2600 | |

| 30 x 3.5 | 41 | 44 | 3150 | |

| 36 x 3.5 | 45 | 48 | 4150 | |

| 42 x 3.5 | 49 | 52 | 5250 | |

Options

- Further numbers of cores upon request

- Integrated Optical Fiber Elements

- Integrated BUS-System