The Smallest High Power Drive in its Class

The Smallest High Power Drive in its Class

High efficiency components and innovative designs make Danfoss VLT high power drives extremely compact as well as simple to commission and operate.

Danfoss’ high power drives are designed for side by side mounting in standard Rittal cabinets.

Drive Flexibility

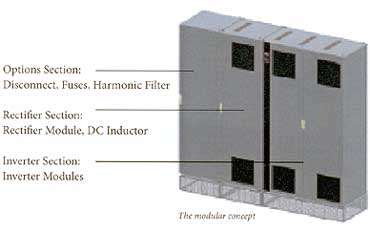

The modular design of the largest VLT drives provide maximum flexibility to satisfy a wide range of application needs.

The modular drive inverters use the same power components as the stand alone drives, reducing the number of spare parts required.

In the event a repair is necessary, the modular drives are designed to allow front door access to all key components, minimising downtime.

Intelligent Cooling – Optimal Operation

Intelligent Cooling – Optimal Operation

Accessories allow for simple installation of IP00 high power VLT series units in standard Rittal TS8 Enclosures. The kit is available for 1800mm and 2000mm high enclosures. The minimum depth of the enclosure is 500mm and the minimum width is 600mm for a single frequency converter to be installed. Multiple drives can be installed side by side in larger Rittal TS8 enclosures of the same height.

Standardised Mounting

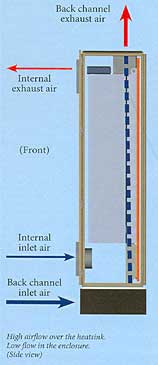

The options provide a mounting solution in standard Rittal TS8 enclosures where the customer can utilise the cooling attributes of the high power drives. The design provides:

- A quick and simple installation with standard options saving time and cost

- Utilisation of the internal fan of the drive to remove the heat avoiding cost of additional fans in the Rittal enclosure

- Provides removal of up to 85% of the heat of the drive through the duct work keeping internal components cooler

- Separate cooling air for the power components keeps the interior of the drive clean of environmental contaminants

- Protection up to IP54 / NEMA12

Dedicated Filters Available

Dedicated Filters Available

Dedicated filters are available to minimise potential harmonic disturbance to other sensitive equipment that are connected to the same power supply. Harmonic disturbance is an issue to be considered with high power applications.

All Danfoss’ drives have built-in DC coils that minimises harmonic disturbance. If additional filtering is specified Danfoss offers a full line of filter solutions.

Fieldbus and Software Tools

Danfoss offers numerous serial communication options and software programmes to support a wide range of applications. Since all units in a VLT drive series utilise a common control principle, the fieldbus or software tool used to control one VLT drive can be used to control any VLT drive – regardless of power or size:

- Features : menu structure and parameter structure are similar throughout the VLT family

- Extending the set-up : commissioning and operation with VLT high power drives is flawless, timesaving and simple

Lower Cost of Ownership

Space savings :

- The smallest high power drives on the market

- Zero side clearance required on the side of the drives

- Front access only is required fro installation and servicing

- Built-in options

Energy Savings :

High efficiency, typically better than 98% reduces overall losses, power consumption and cooling requirements

Optimised Operation :

IP00 / Chassis , IP21 / NEMA 1 and IP54 / NEMA 12 enclosures available as standard

Options to customise the drive :

Unique duct cooling solution along with IP00 / Chassis enclosure provide a cost-effective solution to provide customising of the drive

Time savings :

Same operating software and options for the complete VLT product lines

Local control panels have the same, friendly, familiar language

Maximising uptime :

- Lower component count reduces the number of spare part variants

- Drives fully tested under load at the factory

- Factory designed, tested, certified options increase drive reliability

Specifications

| 380 – 440 V | 441 – 500 V | 525 – 600 V | 690 V | ||||||||||||

| Normal OL110% torque | High OL160% torque | Normal OL110% torque | High OL160% torque | Normal OL110% torque | High OL160% torque | Normal OL110% torque | High OL160% torque | ||||||||

| In Amps | Pn kW | Ih Amps | Ph kW | In Amps | Pn HP | Ih Amps | Ph HP | In Amps | Pn HP | Ih Amps | Ph HP | In Amps | Pn kW | Ih Amps | Ph kW |

| 212 | 110 | 177 | 90 | 190 | 150 | 160 | 125 | 108 | 100 | 86 | 75 | 54 | 45 | 46 | 37 |

| 260 | 132 | 212 | 110 | 240 | 200 | 190 | 150 | 131 | 125 | 108 | 100 | 73 | 55 | 54 | 45 |

| 315 | 160 | 260 | 132 | 320 | 250 | 240 | 200 | 155 | 150 | 131 | 125 | 86 | 75 | 73 | 55 |

| 395 | 200 | 315 | 160 | 361 | 300 | 302 | 250 | 195 | 200 | 155 | 150 | 108 | 90 | 86 | 75 |

| 480 | 250 | 395 | 200 | 443 | 350 | 361 | 300 | 242 | 250 | 195 | 200 | 131 | 110 | 108 | 90 |

| 600 | 315 | 480 | 250 | 600 | 450 | 443 | 350 | 290 | 300 | 242 | 250 | 155 | 132 | 131 | 110 |

| 658 | 355 | 600 | 315 | 658 | 500 | 540 | 450 | 344 | 350 | 290 | 300 | 195 | 160 | 155 | 132 |

| 745 | 400 | 658 | 355 | 745 | 600 | 590 | 500 | 400 | 400 | 344 | 350 | 242 | 200 | 195 | 160 |

| 880 | 500 | 745 | 400 | 880 | 650 | 678 | 600 | 490 | 500 | 400 | 400 | 290 | 250 | 242 | 200 |

| 990 | 560 | 880 | 500 | 990 | 700 | 780 | 650 | 560 | 550 | 490 | 500 | 344 | 315 | 290 | 250 |

| 1120 | 630 | 990 | 560 | 1120 | 800 | 890 | 700 | 630 | 650 | 560 | 550 | 400 | 400 | 344 | 315 |

| 1260 | 710 | 1120 | 630 | 1260 | 900 | 1050 | 800 | 730 | 750 | 630 | 650 | 490 | 500 | 400 | 400 |

| 1460 | 900 | 1260 | 710 | 1460 | 1100 | 1160 | 900 | 890 | 900 | 730 | 750 | 560 | 560 | 490 | 500 |

| 1700 | 1000 | 1460 | 800 | 1530 | 1250 | 1380 | 1100 | 1060 | 1100 | 890 | 900 | 630 | 630 | 560 | 560 |

| 1260 | 1300 | 1060 | 1100 | 730 | 710 | 630 | 630 | ||||||||

| 890 | 800 | 730 | 710 | ||||||||||||

| 1060 | 1000 | 890 | 800 | ||||||||||||

| 1260 | 1200 | 1060 | 1000 | ||||||||||||

VLT Software Tools

For managing drive parameters in systems the new VLT Motion Control Tool MCT 10 is the perfect tool for handling drive related data. Improved from previous VLT software dialogue tool, the MCT 10 offers:

- Project orientation one file that contains all parameter settings and user defined documents

- The Explorer like interface that is user friendly

- SyncPos programming in the same environment, one tool for all tasks

- On-line and off-line commission

- Support of different interfaces RS485, RS232, USB and Profibus (with more to come)

- Import of drive settings from VLT software tools